Improving electrical transformer efficiency is crucial for modern power systems. These devices play a key role in energy distribution, converting voltage levels efficiently. An efficient transformer minimizes energy losses, which leads to reduced operational costs.

Enhancing electrical transformer efficiency involves various strategies. Regular maintenance can address wear and tear, impacting performance. Additionally, selecting appropriate materials can enhance energy transfer while reducing waste. However, not all transformers are designed with efficiency in mind. Some legacy models still operate, which complicates efficiency efforts.

Monitoring performance provides insights into operational shortcomings. Identifying inefficiencies is essential for improvement. Adjusting loads and optimizing cooling mechanisms can further enhance performance. Each step taken contributes to a more sustainable energy future, but challenges remain. Awareness of these issues is vital for progress.

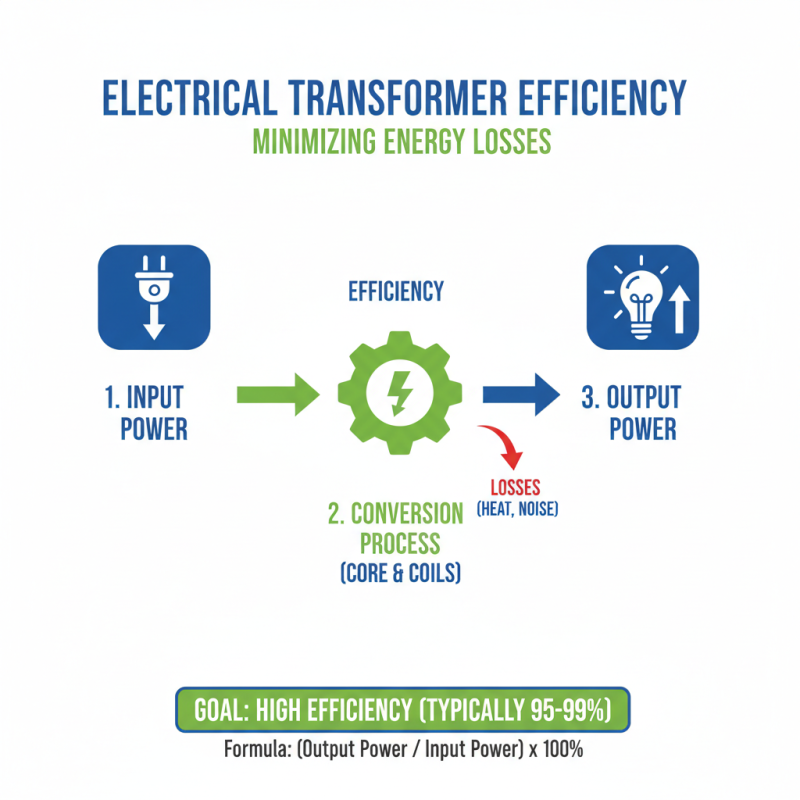

Electrical transformers play a vital role in power distribution. Understanding their efficiency is essential for minimizing energy losses. Efficiency measures how well a transformer converts input power into output power. A common goal is to achieve high efficiency levels, but this can be challenging.

Factors like load conditions and temperature affect transformer performance. At low loads, losses can be significant due to core materials and winding resistance. Some transformers may not operate optimally across all loads. Regular maintenance and monitoring can identify issues. It’s important to check connections and investigate unusual temperature rises.

Improving transformer efficiency often requires a tailored approach. Investing in high-quality materials can help reduce losses. Additionally, analyzing operational data can reveal trends and potential inefficiencies. Small changes, like adjusting cooling methods, can also make a difference. Engaging with experts and learning from industry practices can lead to better results. Embrace the journey of continual improvement in transformer efficiency.

Transformers play a crucial role in electrical systems. Their efficiency directly impacts energy consumption. Several factors influence transformer performance, and addressing these can lead to significant improvements.

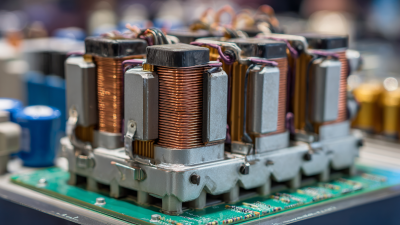

One key factor is load losses, also known as copper losses. They occur due to resistance in windings. A report from the IEEE indicates that these losses can account for up to 50% of total losses in a transformer's operation. Implementing better conductivity materials can reduce this. Adjusting the transformer to operate at optimal loading also helps.

Another critical factor is core losses, which stem from magnetizing the core material. These losses vary based on the quality of the core and its design. According to the National Renewable Energy Laboratory, core losses can exceed 20% of total losses if the material is not optimal. Companies are urged to select high-grade silicon steel or amorphous materials to mitigate these issues. Still, many transformers operate with outdated core designs, leading to inefficiencies. Regular monitoring and upgrades can help address this concern, although many often overlook it.

This chart illustrates various factors affecting the efficiency of electrical transformers, showcasing their impact on performance.

Improving transformer efficiency is crucial for energy savings. According to a report by the International Energy Agency (IEA), transformers account for about 10% of global electricity consumption. Enhancing their performance can significantly reduce electrical losses and lower operational costs.

One effective technique is regular maintenance. Studies show that well-maintained transformers can improve efficiency by up to 5%. Inspections help detect issues like insulation degradation. Neglecting this aspect can lead to unexpected downtime and increased energy waste. Additionally, using advanced monitoring systems can provide real-time data. This helps in identifying performance issues early, yet many facilities still overlook such measures.

Another approach is to optimize the design and selection of transformers. Using lower-loss core materials can yield improvements. The IEA reports that modern designs can achieve efficiencies of over 98%. However, implementing these new technologies can be expensive. Some organizations hesitate, fearing high upfront costs may not justify long-term savings. Balancing initial investments against potential gains is a constant challenge in the industry.

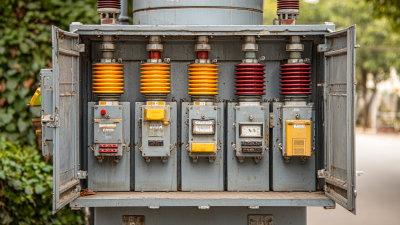

Regular maintenance of electrical transformers is essential for ensuring operational efficiency.

A well-maintained transformer can operate at over 98% efficiency, according to industry reports.

However, neglecting maintenance can lead to a rapid decline in performance. Routine checks are crucial to identify signs of wear and tear early.

Monitoring oil quality is one key maintenance strategy. Contaminated oil can lead to overheating and reduced insulation efficiency.

A study by the IEEE found that over 30% of transformer failures resulted from inadequate insulation due to poor oil conditions.

Performing regular oil tests can prevent costly breakdowns and extend transformer lifespan.

Periodic visual inspections are equally important. Inspecting for signs of physical damage, such as leaks or rust, is vital.

Data shows that more than 25% of transformers experience issues from physical deterioration.

Relying solely on operational metrics may not be enough. Transformer's health must be assessed holistically. Sometimes, we overlook simple issues that can lead to major problems later.

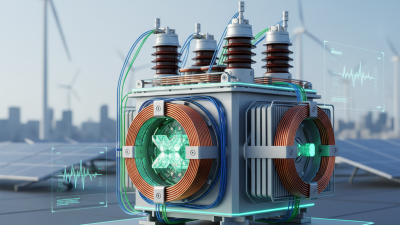

Emerging technologies are transforming the design of electrical transformers. These innovations focus on enhancing efficiency and reducing energy loss. For instance, new materials like amorphous steel improve core performance. This change minimizes heat generation, leading to better efficiency.

Implementing smart monitoring systems is another way to boost transformer efficiency. Real-time data analytics can identify energy waste patterns. Operators can adjust operations based on this information. Predictive maintenance is an emerging trend that promises significant benefits. It helps avoid costly failures and optimizes performance over time.

To further enhance efficiency, consider these tips: regularly maintain transformers to ensure they operate at peak performance. Also, invest in advanced cooling solutions to reduce heat. Lastly, train staff in the latest monitoring technologies to fully leverage these advancements. These practical steps are crucial for future-ready electrical systems.

| Tip | Description | Emerging Technology | Efficiency Gain (%) |

|---|---|---|---|

| Utilize Amorphous Steel Cores | Reduces no-load losses compared to traditional silicon steel cores. | Amorphous Alloy Technology | 10-15% |

| Implement Smart Monitoring Systems | Enables real-time data analysis to optimize operation. | IoT Sensors & Data Analytics | 5-20% |

| Overhaul Cooling Systems | Improves heat dissipation, extending transformer lifespan. | Liquid Immersion Cooling | 7-12% |

| Optimize Load Management | Ensures transformers operate within optimal load ranges. | Smart Grid Technology | 8-15% |

| Adopt Low-Carbon Materials | Minimizes environmental impact while maintaining efficiency. | Eco-Friendly Insulating Fluids | 2-5% |